Thermal Scanning

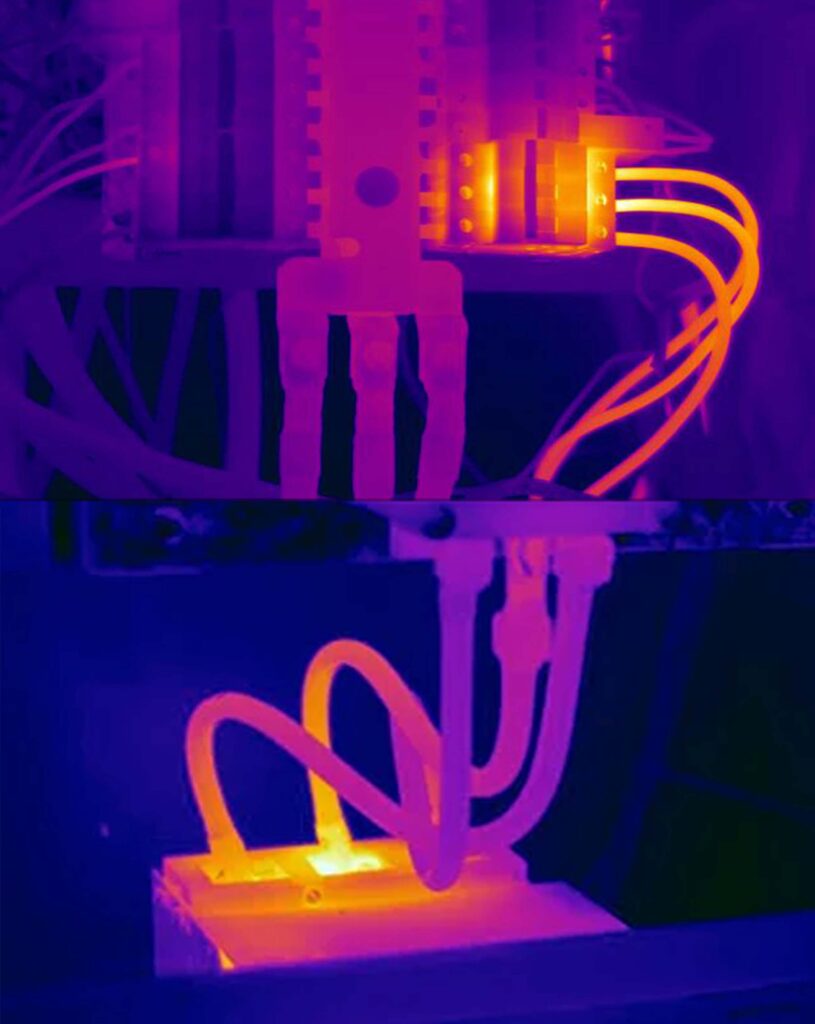

“Unlocking the Invisible Advantage” Technology that converts invisible radiation patterns emitted by objects into visible images for feature extraction and analysis, relying on long-wave infrared radiation rather than visible light.

What is Electrical Thermal Scanning?

Electrical thermal scanning—also known as thermography or infrared imaging—is a non-invasive, non-destructive technique used to inspect electrical systems and equipment. By using a thermal imaging camera, this method captures heat signatures and temperature variations in components such as cables, circuit breakers,<br>switchboards, transformers, and other electrical infrastructure.<br>These thermal images help identify potential faults—such as loose connections, overloaded circuits, or failing components—before they lead to equipment failure, fire hazards, or costly power outages. Early detection enables proactive maintenance and enhances the safety and reliability of your electrical systems.<br><br>At Austec Group, our team consists of licensed electricians and certified thermographers who deliver high-quality thermal imaging services. We utilize advanced thermal imaging technology and software to diagnose issues accurately and provide<br>you with a comprehensive report, including clear findings and practical recommendations.<br>

How Often Should Thermal Scanning Be Conducted?

Unlike Residual Current Device (RCD) testing, there is currently no legal mandate or fixed schedule for electrical thermal scanning in Australia. However, it is increasingly being adopted as standard practice across commercial, industrial, and institutional settings due to its value in preventative maintenance and its growing relevance in insurance compliance. If you’re conducting thermal scanning to meet insurance requirements, it’s essential to consult directly with your insurer, as frequency expectations can vary.

Office buildings or low-load environments: Every 1 to 3 years, depending on electrical load and system age.

Industrial, manufacturing, or military facilities: Annually, due to higher power demands and greater risk factors.

High-risk or high-load sites (e.g., mining operations): More frequent inspections are recommended, potentially every 3 to 6 months, depending on equipment exposure, environmental conditions, and operational intensity.

.

Safety First

Ensuring the safety of people and property is the highest priority for anyone managing a public or commercial facility. In Australia, over 5,000 fire damage claims are made each year for commercial premises. Alarmingly, around:

20% of structural fires occur in retail spaces

20% in accommodation and food services

16% in agriculture, forestry, and fishing

14% in manufacturing

While causes like cooking equipment and heating systems are common, the leading cause of commercial fires is faulty electrical equipment, responsible for 1 in every 5 incidents. Improving safety starts with proactive measures. While smoke alarms, emergency procedures, and sta training are essential, nothing is more eective than prevention. Routine thermal scanning of switchboards, fuse boxes, control panels, and other electrical infrastructure can detect potential faults before they become dangerous, reducing the risk of fire and system failure.

Advanced Detection

Electrical faults often start small—through loose terminations, corroded or degraded connections, malfunctions, or unbalanced electrical loads. These issues are typically invisible to the naked eye and cannot be identified through standard visual inspections. Left undetected, they can lead to fires, equipment damage, costly downtime, and major safety hazards. Thermal scanning uses advanced infrared imaging technology to detect these hidden

risks. By measuring infrared radiation (heat) emitted by electrical components, the system creates visible images that highlight abnormal temperature patterns, or “heat blooms,” associated with faults. Our thermography-certified technicians inspect equipment under normal load conditions, ensuring accurate diagnostics without operational disruption. With this non-invasive method, we can identify problems early—long before they become critical—giving you the insight and time to take corrective action.

Preventative Maintenance

Electrical systems work quietly and reliably—until they don’t. When faults occur, they can pose serious safety risks, lead to equipment damage, and cause major operational disruptions. While many electrical issues are simple and inexpensive to fix when caught early, undetected faults can escalate into fires, extensive repairs, and prolonged downtime. In commercial, industrial, and manufacturing settings, unplanned outages can result in significant productivity losses. While backup generators may help maintain power supply, an internal electrical fault can halt operations entirely until it is located and resolved—often at great cost. Integrating thermal imaging into your routine maintenance schedule offers a smart, cost-effective way to detect electrical issues before they become critical. This noninvasive method enables early fault identification, reducing the risk of breakdowns, improving safety, and extending the life of your equipment. A small investment in preventative thermal scanning today can help avoid major repairs and costly downtime tomorrow.

Insurance Compliance

While thermographic inspections of electrical equipment and switchboards are not legally mandated in Australia, they have increasingly become a standard insurance requirement for commercial properties. Many insurers now expect regular thermal imaging to be performed as part of a facility’s risk management and preventative maintenance program. For example, QBE Insurance recommends that thermal imaging of electrical switchboards be carried out by licensed electricians who meet strict regulatory and safety requirements, and who hold appropriate thermographic qualifications. These qualifications typically include Level 1–3 certification through an Approved Testing Body, as specified in AS/ISO 18436-7: Condition monitoring and diagnostics of machines — Requirements for qualification and assessment of personnel – Part 7: Thermography. At Thermal Scanners, all our technicians are fully certified in accordance with these standards. Our inspections are performed with precision and professionalism, and each scan includes a comprehensive, insurance-compliant report for submission to your insurer or risk assessor. Protect your business, meet insurance obligations, and reduce the risk of electrical faults—book your inspection with confidence today.

Thermal Imaging Report

Every thermal scan we conduct is performed by a thermography-certified technician and includes a comprehensive, insurance-compliant report designed to meet the requirements of insurers, auditors, and facility managers.

Our reports provide a clear and actionable overview, including:

Detailed scope of works – outlining the systems and equipment inspected

Thermal and visual images – side-by-side imagery highlighting any identified exceptions

Precise location of each fault – clearly labelled for easy identification and rectification

.

Date and time stamp – confirming when the scan was conducted

Priority rating – to help prioritize repairs based on severity and risk

Possible causes – expert insights into the most likely root causes of each

issue

.

Technician credentials – including certification level and relevant qualifications

.

Thermal Scanning for Solar Systems

Thermal imaging isn’t just for switchboards and electrical panels—it’s also an effective tool for identifying faults in solar power systems and solar hot water units. Using infrared technology, thermal scanning can reveal defective cells, damaged panels, or blockages that are not visible during a standard visual inspection.

These faults can result from:

Improper or substandard installation

Manufacturing defects

Weather-related damage (e.g., hail, dust, or debris buildup)

Internal blockages from rust, mineral buildup, or heavy metals (particularly in solar hot water systems)

Since many of these issues are hidden from plain sight, thermal imaging allows you to “see inside” the system and assess how each component is performing under load.

Important: Thermal scanning of solar systems must be carried out on sunny days, under normal operating conditions, when inverters and panels are actively generating power. This ensures accurate thermal data and fault detection.

Why scan your solar system?

Verify performance and efficiency—especially during warranty periods

Conduct quality assurance post-installation

Assess for damage after weather events like hail or dust storms

Investigate unexpected increases in your electricity bill

Photo of Existing Panel without Themal Scanning

Photo of Existing Panel with Themal Scanning

If your power bills are rising and you rely on solar, now is the time to schedule a thermal inspection to make sure your system is working as efficiently as it should.